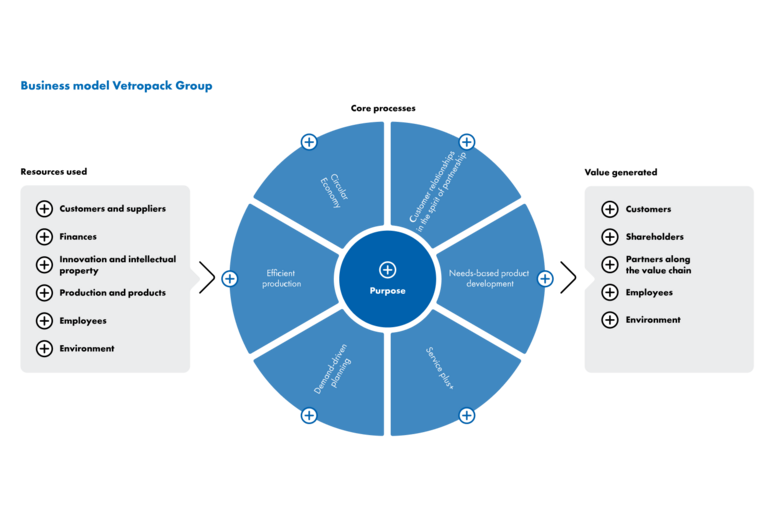

The force that motivates us to create value

The Vetropack Group's financial success is not the only pillar of our value creation model. As well as our shareholders, our achievements should also benefit our customers and employees, our upstream and downstream partners in the value chain, and the environment.

At the core of our business model is the company's purpose: "We make it possible for everyone to enjoy food and beverages in the most elegant, safest and most responsible way." This is the maxim that motivates all of our employees to take action – the foundation for creating unique products and services of high quality.

Our company's purpose

WE

We are an exchange-listed Swiss family enterprise that has fostered honesty, commitment and transparency ever since the year our company was founded. Strong values, a work culture based on partnership and an ambience of collaboration: these are Vetropack's hallmarks. When we say “we”, we mean every single person who works for – and with – our company. Each and every individual plays a key part in our company’s success.

FOR EVERYONE

We care deeply about our consumers and their needs. That's why we help our direct customers to provide the best possible service and support for their customers.

FOOD AND BEVERAGES

We can look back on a lengthy tradition in the food and beverage industry, and we have an intimate knowledge of all its facets. We also have a deep understanding of the industry's stakeholders and their needs. Drawing on these assets, we focus on producing glass containers for this industry – and we aspire to offer the very highest quality and the best value in everything we do.

ELEGANT

For us, the elegance of glass stems from its simplicity, long-lasting beauty, and the variety of shapes and colours that this material offers for high-quality packaging solutions. In the food and beverage sector, packaging helps to communicate brand and quality to the end consumer. Glass is the most elegant material available to achieve this purpose. The look and feel of glass make a customer’s brand come alive for each and every consumer. And when we say "most elegant", we also mean the emphasis we place on designing products individually to meet customers' specifications. We offer a varied range of services, and we aim to build close, long-lasting relationships so we can develop a profound understanding of our customers.

SAFE

Safety for everyone is our overriding concern: we focus on high-quality products that are constantly updated and optimised. Thanks to its natural origin and inert structure, glass is the perfect material for food-safe packaging. We take a holistic approach to safety, and we help our customers to optimise their value chains so as to guarantee the safety of their consumers.

RESPONSIBLE

We regard glass as the most sustainable packaging solution of all, because it is manufactured from purely natural raw materials, is 100% recyclable, and can be reused an infinite number of times. But we also believe that our responsibility goes far beyond the product itself: it also includes acting in a spirit of solidarity, taking responsibility for the environment, and managing our business economically and efficiently. We aim to make our carbon footprint as small as possible throughout the value chain. Being aware of our responsibilities, we see recycling as the key to optimising the product life cycle, including end-of-life management. Because we also feel committed to helping our customers succeed, we offer them services that go beyond our glass products – thus enabling them to achieve the success they seek.

Core processes

Customer relationships in the spirit of partnership

Vetropack’s holistic value creation is based on customer relationships in the spirit of partnership. Huge demand on the glass container market has prompted us to invest more than the industry average in efforts to increase the availability and safety of our products. In this way, we secure the loyalty of our key customers and attract new ones. By identifying customer needs at an early stage, we can successfully expand our market positions and develop new areas of activity. To achieve these goals, we are also venturing into new lines of business throughout the value chain. Vetropack’s holistic value creation is based on customer relationships in the spirit of partnership. Huge demand on the glass container market has prompted us to invest more than the industry average in efforts to increase the availability and safety of our products. In this way, we secure the loyalty of our key customers and attract new ones. By identifying customer needs at an early stage, we can successfully expand our market positions and develop new areas of activity. To achieve these goals, we are also venturing into new lines of business throughout the value chain.

Needs-based product development

We set the trends for innovation in the glass packaging industry by collaborating closely with customers, suppliers and industry associations – right from the outset. To complement our own concepts and the ideas originated by our customers, we often commission external designers to develop product designs. Whichever route is chosen: comprehensive requirements must be specified for future glass packaging so that development work can be driven ahead efficiently, and to bring innovative solutions to market as quickly as possible.

Service plus+

We offer our customers a wide-ranging portfolio that goes well beyond the production of glass packaging as such. Our services include packaging design, high-quality production and on-time supply, advice and support in areas such as packaging analysis, bottling, conditioning and closure technology, glass finishing and labelling – and we can even assist with calculating environmental footprints. In these various ways, we help our customers to optimise all the steps involved in the process of launching new types of glass packaging. Going forward, we are keen to expand our service offering based on our existing expertise, so as to continue strengthening customer loyalty and opening up new business opportunities along the value chain.

Demand-driven planning

We work continuously to optimise product planning and availability. We use demand forecasts as the basis for aligning all our processes, from raw materials purchasing and production scheduling through to shipping of finished products. Optimal process coordination allows us to maximise utilisation of capacity in all our production facilities. To achieve this, we operate a digital system that will consolidate all aspects of production planning into one single, Group-wide process in the future. The overall objective is to make more efficient and flexible use of our production capacities.

Efficient production

To achieve our goal of energy-efficient production at optimum cost, we invest continuously to make our production lines more efficient and more flexible. This also allows us to process smaller batch sizes and varied product segments, so we can respond better to seasonal demand peaks in the beverage market. Guided by our digitalisation roadmap, we are leveraging the opportunities offered by automation to simplify repetitive production and administration processes. Our Group is also investing extensively in production facilities and logistics to ensure reductions in energy consumption and related CO2 emissions. Our Strategy 2030 includes the key target of reducing greenhouse gas emissions from each metric ton of glass produced by 30% as compared to 2019 levels.

Circular economy

Our business model supports the transition to a circular economy, because it is based on natural raw materials that are almost infinitely reusable. Vetropack was already a pioneer of glass recycling back in the 1970s and nowadays, we collect used glass for recycling in all the countries where we operate glassworks. In many countries, we collaborate with special-purpose associations to maximise collection rates. We are also driving the development of returnable bottles ahead: these are made in part from resource-efficient lightweight glass, so they are even easier to handle. As part of our Strategy 2030, we have set ourselves the target of reaching a cullet share of at least 70 percent in Group-wide production by 2030.