Vetropack at drinktec 2025: innovations for a sustainable future of glass packaging

15.09.2025: At drinktec 2025 in Munich, the Vetropack Group will showcase its versatile portfolio of resource-saving and efficient glass packaging solutions. Among the highlights are the new Total Cost of Ownership calculator and the new brand appearance of Rezon – under which Vetropack now presents its thermally strengthened lightweight glass bottle, in line with the start of its industrial production in 2026. The proven technology remains unchanged while the brand has been further refined and aligned with the sustainable potential of the solution. Visitors to drinktec 2025 can explore the innovations first-hand and receive individual consulting at the company's booth in hall C2, booth 160.

Three years ago, Vetropack unveiled the world's first thermally strengthened lightweight glass bottle, Echovai, at the same trade fair – a breakthrough in the industry. Years of development work produced a bottle that is up to 30 percent lighter while delivering high durability and a long lifespan. Consequently, the market response was positive: In 2024, the bottle became the standard solution for the Austrian brewing industry. Brands such as Gösser and Rieder have implemented the bottles successfully. Several awards, including the WorldStar Award, the Austrian State Prize for Smart Packaging, and the Swiss Packaging Award, confirm the performance of the technology.

A new brand for new possibilities

With the upcoming start of serial production in 2026, Vetropack is opening a new chapter: Echovai becomes Rezon. The new name stands for progress as well as innovative and sustainable potential. This goes not only for returnable systems but also selected single-use applications. Rezon creates new opportunities for the beverage industry, especially where light weight and a premium glass appearance are crucial.

Sustainability that pays off

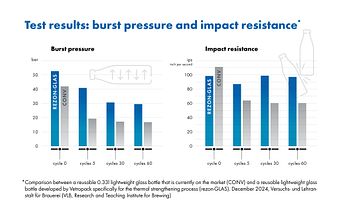

The specially developed thermal strengthening process gives the bottles exceptional durability. At the end of 2024, the Versuchs- und Lehranstalt für Brauerei (VLB, Research and Teaching Institute for Brewing) tested a reusable 0.33l lightweight glass bottle that is currently on the market and a reusable lightweight glass bottle developed by Vetropack specifically for the thermal strengthening process. The comparison showed that even after 60 use cycles, the thermally strengthened bottles exhibited far greater internal pressure and impact resistance than standard bottles. With an average burst pressure of 29.5 bar, they are almost twice as strong as the conventional version of the reusable bottles, which reach an average of 16.8 bar – a clear advantage in terms of reusability, product safety, and product life span.

The reduced weight not only saves beverage manufacturers material but also lowers transport costs and CO₂ emissions. Combined with the bottle’s high number of use cycles, this substantially decreases resource consumption per use. As a result, beverage producers benefit from both improved sustainability and economic efficiency – reducing the total cost of ownership (TCO) across the entire life cycle of the bottle.

drinktec 2025: Circularity in practice

In line with the trade fair's main theme of ‘Circularity & Resource Management’, Vetropack – with Rezon as part of its portfolio – will demonstrate how sustainable glass packaging solutions and economic efficiency can go hand in hand. Visitors to the booth will be able to try out the new Total Cost of Ownership calculator, which enables beverage manufacturers to precisely evaluate the cost-effectiveness of packaging solutions as early as the planning stage.

Vetropack experts will be on hand for in-depth discussions on current market needs and to consult on customised packaging solutions.

Visit us in hall C2, booth 160 at drinktec 2025 from September 15 to 19!

Downloads