Rezon – the technology

Tempered glass has been used in car windscreens for a long time but had so far reached its limits when it comes to glass packaging. The reason: during the tempering process, the bottle blanks must be heated to a high temperature and then shock-cooled to create the necessary internal tension and stability. This is not a problem with flat glass, but the wall thickness distribution of glass bottles varies – which can lead to cracks during tempering. This made profitable production of tempered glass containers impossible.

Vetropack's research and development team spent almost ten years working on a manufacturing process for strengthened lightweight glass bottles. The resulting technology made it possible to thermally strengthen glass bottles for the first time. To date, Vetropack is the only glass packaging manufacturer worldwide to offer this solution. Due to the high tensions occurring in the glass, the strengthening process places particularly high demands on both the quality of the bottles themselves as well as the production process and the equipment.

«We adjust the entire strengthening process very precisely to the individual container and its shape. It’s a very sophisticated, technologically demanding process that can’t be implemented on just any production line. »

Outstanding performance – proven in the lab and in practice

The bottles produced with this technology were successfully tested on the market as part of a pilot project with the Mohrenbrauerei. The 0.33 litre returnable bottles saved around 30 percent in weight compared to standard returnable bottles, which significantly reduced emissions and costs in logistics. The bottles also proved their durability. After three years and up to twelve use cycles, there was hardly any damage, or wear to the contact surfaces – one of the main reasons why standard reusable bottles are discarded for aesthetic reasons. In fact, the majority of the bottles still fit the parameters of new bottles. "This was practical proof of the outstanding performance that the bottles had achieved in laboratory tests before and since then," says Daniel Egger.

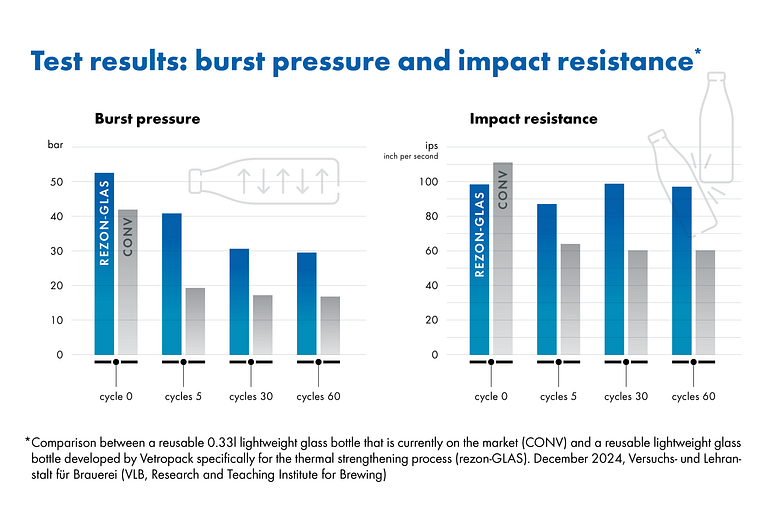

In fact, multiple tests by the Versuchs- und Lehranstalt für Brauerei (VLB, Research and Teaching Institute for Brewing) show that the bottles made of thermally strengthened glass develop significantly less wear (scuffing) on the contact surfaces and withstand impact better. At the end of 2024, the organisation last tested two versions of the 0.33-litre standard reusable bottles that were introduced in Austria – a conventional, non-strengthened version and a thermally strengthened one. The comparison showed that even after 60 use cycles, the strengthened bottles exhibit far greater internal pressure and impact resistance than standard bottles. With an average burst pressure of 29.5 bar, they are almost twice as strong as the conventional version of the reusable bottles, which reach an average of 16.8 bar. "We know from lab tests and practical experience that our strengthened lightweight glass bottles can be used for a significantly higher number of use cycles than conventional reusable bottles – making them an even more ecological solution."

Kick-off for widespread use

At the beginning of 2024, a specially developed 0.33-litre reusable bottle was introduced as a particularly sustainable standard solution that is available to the entire brewing industry in Austria. The first user of the new standard bottle was the beer brand Gösser, which has been filling its first organic beer – "Gösser Biostoff Lager" – in Vetropack's robust lightweight glass bottles since March 2024. In 2025, the private brewery Ried also joined in, gradually switching its entire range to the new standard reusable system and lightweight bottles.

Currently, the lightweight bottles are produced at the plant in Pöchlarn, Austria, where Vetropack is now preparing for large-scale production from summer 2026. To this purpose, the company has been operating a dedicated test machine for the thermal strengthening process since the end of 2024, which can be used to validate bottle geometries with just a few sample pieces and optimise them for serial production. In the future, other Vetropack plants may also be upgraded for Rezon production.

Ideal for reusable, alternative for single-use

The strengthened glass bottles deliver particularly high material savings, which plays a key role for returnable bottles that must be transported back to the bottling plants repeatedly. Because their resilience also allows a high number of use cycles over a long product life span, beverage manufacturers can manage with fewer new bottles overall, making these bottles a particularly ecological solution, especially in reusable systems. However, the bottles are suitable for applications besides reusable systems. They also offer great potential in the single-use segment, where weight often plays a decisive role. Rezon could offer a lighter, resource-saving alternative, which also impresses with its long-lasting premium appearance.

"In the long term, we are aiming for a more user-friendly return and refill system with 100 percent reuse of the bottles," explains Daniel Egger. "We have already implemented a solution to optimise the traceability of our thermally strengthened lightweight glass bottles. Using a specific data matrix code on each bottle, we can link any data to the product unit. In the future, this should connect previously separate worlds in the value chain and ensure seamless traceability along the entire supply chain – from production to bottling and to the end customer."