Vetropack modernises furnace at Hum na Sutli

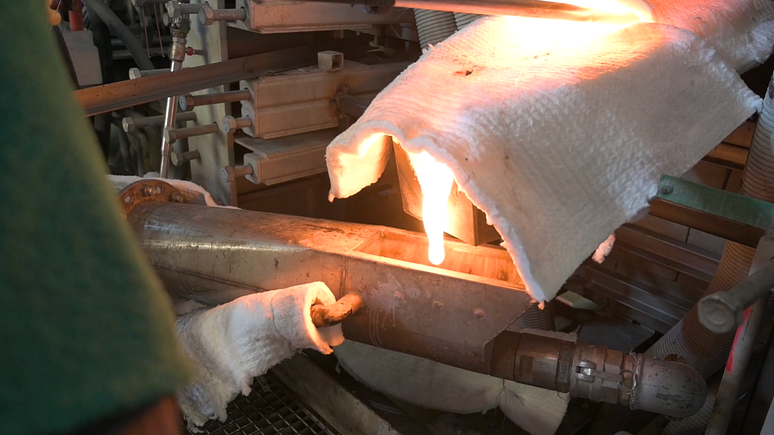

02.09.2024: The Vetropack Group, one of Europe’s leading glass packaging manufacturers, is set to modernise one of the three furnaces and the corresponding glass forming machines at its Croatian plant in Hum na Sutli. This strategic upgrade is poised to enhance production capacity, optimise energy efficiency, and reduce environmental impact. Vetropack Straža d.d. commences draining of the furnace today and expects the first glass produced on the new equipment by December of this year.

«The new furnace and equipment are designed to reduce energy consumption and to lower our specific emissions.»

After draining is complete, the current flint furnace at the Vetropack Straža d.d. plant in Hum na Sutli, Croatia, will be demolished. Following the rebuild and a heat-up period of approximately one to two weeks, the modernised furnace is expected to produce its first glass by December. As a key part of this modernisation project, Vetropack Straža d.d. will also introduce new glass forming machines and a completely new set-up for the cold end including newest inspection technology to guarantee highest product quality standards.

Notably, one of the new installations will be a servo-electric driven NIS machine, a first for Vetropack Straža d.d. An optimised layout of the whole plant set-up is set to improve the flow of production. These upgrades are not only crucial for maintaining the high standards of glass packaging products but also essential for ensuring the longevity and efficiency of manufacturing operations.

Higher capacity, lower carbon emissions

The modernisation will result in an increase in production capacity, enabling Vetropack Straža d.d. to better serve customers while meeting growing market demands. “I am pleased to say that the modernisation project is carried out in a very time-efficient way. This enables us to bring our product back on the market very soon,” comments Mario Berc, Technical Manager at Vetropack Straža d.d. With the upgrade, Vetropack Straža d.d. will also achieve a higher furnace output, enabling the production of more tonnes of glass per square metre, thus saving space and optimising production costs.

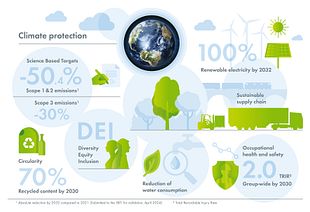

“I want to highlight that this upgrade also reflects our dedication to environmental stewardship. The new furnace and equipment are designed to reduce energy consumption and to lower our specific CO2 emissions, thereby minimising our carbon footprint and contributing to our sustainability goals,” Berc adds. In April 2024, the Vetropack Group had defined and submitted its targets for reducing CO2 emissions to the Science Based Targets initiative (SBTi). By 2032, Scope 1 and 2 emissions are to be reduced by 50.4 percent and Scope 3 emissions by 30 percent. In order to achieve these targets, the Vetropack Group is pushing ahead with modernisation measures such as the one in Hum na Sutli.

Téléchargements

- PI_EN_Vetropack_FurnaceRefurbishing.pdf (pdf)